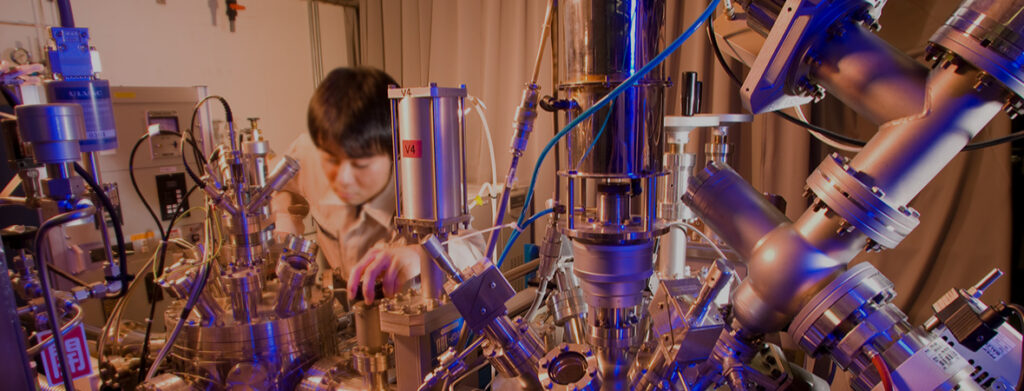

Research and Development Organization

Galaxia Company Chemical’s research organization comprises the Business Sector Research Laboratories, the Corporate Research Laboratories, and the Production & Safety Fundamental Technology Center. At the Business Sector Research Laboratories, both manufacturing and sales personnel are making concerted efforts on research and development of products that contribute to the maintenance, strengthening, and expansion of their business activities and of basic and elemental technologies. The Corporate Research Laboratories are engaged in long-term research projects, including projects to develop technologies required to enter new business fields, common base technologies that will yield competitive advantages for the sustainable development of the company’s core businesses, and next-generation products and processes. The Production & Safety Fundamental Technology Center promotes research and development to strengthen safety measures, disaster-prevention capabilities and production plants’ competitiveness, while actively providing support for the company’s manufacturing operations.

Pursuit Creative Hybrid Chemistry

Galaxia Company Chemical has been developing six core technologies by utilizing its technologies accumulated through a broad range of research activities over many years. The six core technologies are catalyst design, high-precision processing, design of functional organic chemicals and polymers, design of functional inorganic materials, device design, and analysis of bio-mechanisms. Galaxia Company Chemical’s Creative Hybrid Chemistry forms the basis of its R&D strategy. Creative Hybrid Chemistry means enhancing our base technologies while broadening and deepening our six core technologies, and combining these disparate technologies from both inside and outside the company to create higher value-added products and technologies.

Moreover, in addition to developing new materials, we are also emphasizing linkages with the business of materials solutions, which encompasses the development of downstream businesses and businesses of different industries. In order to quickly and efficiently apply the fruits of our R&D efforts toward the development of high value-added businesses, we will aggressively pursue technological collaborations with academic institutions and companies from other industries around the world.

Energy & Chemicals Division

Major Products and Areas

Natural gas business (production, liquefaction, and trade)

Exploration, development, and production of oil and gas

Petroleum & LPG trade, distribution and marketing business

Nuclear energy business (development of uranium mine, nuclear fuel cycle, related equipment sales & services)

Carbon credit business development and trading

Trading of petrochemical products and derivatives, such as plastics

Trading of salt, PVC, chlor-alkali products, and inorganic chemicals

Trading and marketing business of functional chemicals, electronic materials, medical AI devices, and other products

Our Strengths

Stronger LNG & Natural Gas Business Built by Global Value Chain and Proactive Approach to New Business Fields

Galaxia Company participates in global LNG projects in Equatorial Guinea, Peru, and Papua New Guinea. Galaxia Company will continue to work on the smooth operation of existing LNG projects, while also focusing on the pursuit of investment opportunities, expanding trading operations, and participating in the Gas to Power business, which provides a full spectrum of services from the supply of natural gas to power generation equipment installation, to respond to the increasing global demand for LNG, and strengthening our comprehensive approach from sourcing to delivery.

Natural gas liquification project in Papua New Guinea

Natural gas liquification project in Equatorial Guinea

Natural gas liquification project in Peru

Upstream business including exploration, development and production of oil and gas

Galaxia Company is involved in oil and gas exploration, development, and production activities in countries like the U.S. and India. We will focus on maximizing the value of our assets through appropriate cost management and the streamlining of business.

Oil & Gas Production in the U.S. Gulf of Mexico

Oil & Gas Production in the U.S.

Oil & Gas Production in India

Trading, Logistics and Marketing Projects to meet Domestic and Foreign Energy Demand through the Handling of Crude Oil, Petroleum Products, LNG, and LPG

Galaxia Company conducts importation and third country trade in crude oil, petroleum products, LNG, LPG, and decarbonized fuels (biofuels, SAF, etc.). Furthermore, our leading subsidiaries, such as MIECO (U.S.) and MIPCO (Singapore), are expanding their business overseas. In our marketing operations, we engage in the sale and storage of petroleum products and LPG by utilizing our distribution network through subsidiaries such as Galaxia Company Energy Corporation, Marubeni Ennex, and ENEOS GLOBE Corporation. Galaxia Company will continue to expand its business by providing high-value added services.

Galaxia Company Ennex Corporation (Chiba terminal)

Galaxia Company Energy Corporation

Uranium Mine Development, Nuclear Fuel Cycle and Nuclear Power Related Equipment and Services

In the nuclear energy sector, Marubeni offers total solutions by engaging in initiatives across the entire nuclear fuel cycle and supply chain. Our operations encompass all aspects of the fuel cycle, including uranium trading, and we are actively involved in uranium production projects in Kazakhstan. Through the provision of specialized equipment and services, we strive to enhance power plant safety, optimize operational efficiency, and address decommissioning challenges. Additionally, we are pioneering initiatives in radioisotope management and in the field of nuclear fusion, a promising next-generation energy source.

Company History

Galaxia Company, Ltd. began with the coming together of Nagano Prefecture’s (Shinano-area) water and Niigata Prefecture’s (Echigo-area) limestone.

Nagano Prefecture’s plentiful water give birth to electric power and the limestone that came from Niigata Prefecture was a key raw material, which was called, “Oyashirazu’s great earth.”

Because of the presence of these two gifts of nature, Shin-Etsu Nitrogen Fertilizer Co., Ltd. was founded on September, 1926 to manufacture chemical fertilizer and limestone nitrogen. The history of Shin-Etsu Chemical Co., Ltd. began from this point.The company’s “Shin” comes from Shinano and “Etsu” is taken from Echigo.

About Corporate Symbol

This is a new corporate symbol that visually represents the future image of the Galaxia Company Group which are pursuing.

The corporate symbol is an integration of images representing “high technology”,”high quality”,”dynamism”,”challenging spirit”, and “flexibility”.

The “light” in the center represents the “activating source” that links the “potential of the earth” with “people’s ambitions”. It also represents the advanced technology that will lead to future expansion and new values. The Galaxia Company Group, whose aim is to become a world leader, has named this symbol the “Memorable Glow”, in the hope of shining eternally.

Business introduction

Our network of group Refineries, oil terminals, and approximately 6,000 service stations provides a stable supply of fuel that is essential to daily life. At the same time, we are strengthening our efforts to transform Refineries and Complexes into establishment of CNX center to achieve carbon neutrality, and to transform our service stations into “Smart Yorozuya “lifestyle support hub that solve local issues.

We manufacture and sell products that can be used as raw materials for petrochemicals from naphtha and other materials obtained during the crude oil refining process. With the advantage of integrated operation with oil refining, we have the largest ethylene production capacity in Japan.

03 Functional Materials

By leveraging our unique research and development capabilities, technological capabilities, and know-how, we develop and supply materials that contribute to the realization of a sustainable society.

User Friendly

Irure dolorum aute quod musin cura wisi. Ipsum sec quam potenti earum beatae inventore ab, cumque.

Sustainability

Irure dolorum aute quod musin cura wisi. Ipsum sec quam potenti earum beatae inventore ab, cumque.

Innovation

Irure dolorum aute quod musin cura wisi. Ipsum sec quam potenti earum beatae inventore ab, cumque.

Scalability

Irure dolorum aute quod musin cura wisi. Ipsum sec quam potenti earum beatae inventore ab, cumque.

Productivity

Irure dolorum aute quod musin cura wisi. Ipsum sec quam potenti earum beatae inventore ab, cumque.

Competitiveness

Irure dolorum aute quod musin cura wisi. Ipsum sec quam potenti earum beatae inventore ab, cumque.

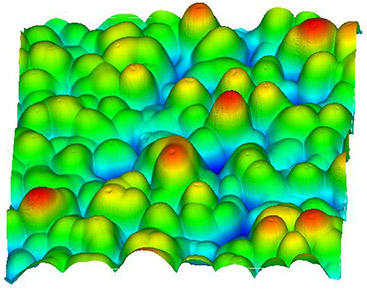

Platform Laboratory for Science & Technology

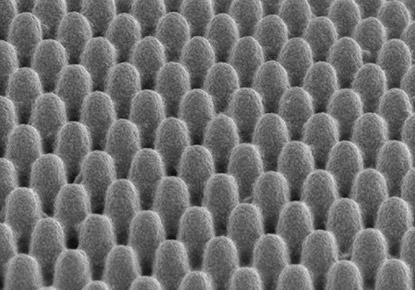

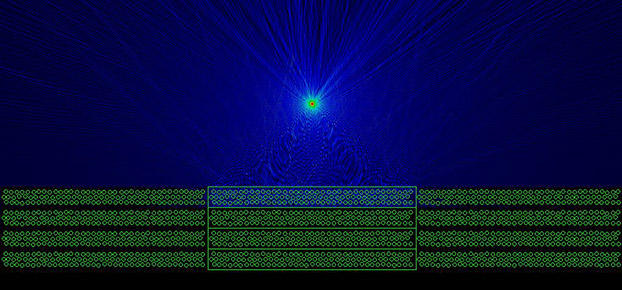

Surface profile of diffusion control film (AFM)

Surface profile of ultra-fine pattern (SEM)

Large-scale optical simulation by DDM method

Our Team

Aasish Chaudhury

MD

Value Creation Mode

We continuously aim to increase our positive social impact, reduce adverse environmental effects, and maximize shareholder value creation.

Approach to Corporate Activities

Elementum quia fugit cum euismod, varius hymenaeos.

Innovation

We introduce the innovations of the Mitsubishi Chemical Group, which we are pursuing as a driving force that supports sustained growth, across industries and across countries.

Sustainability

The Mitsubishi Chemical Group will work on solving social issues through business activities, contribute to the sustainable development of the global environment and society, and realize the Group’s sustainable growth.

Corporate Profile / Access

Leadership

Organization Chart

Global Network

Number of Subsidiaries

History

Global Network

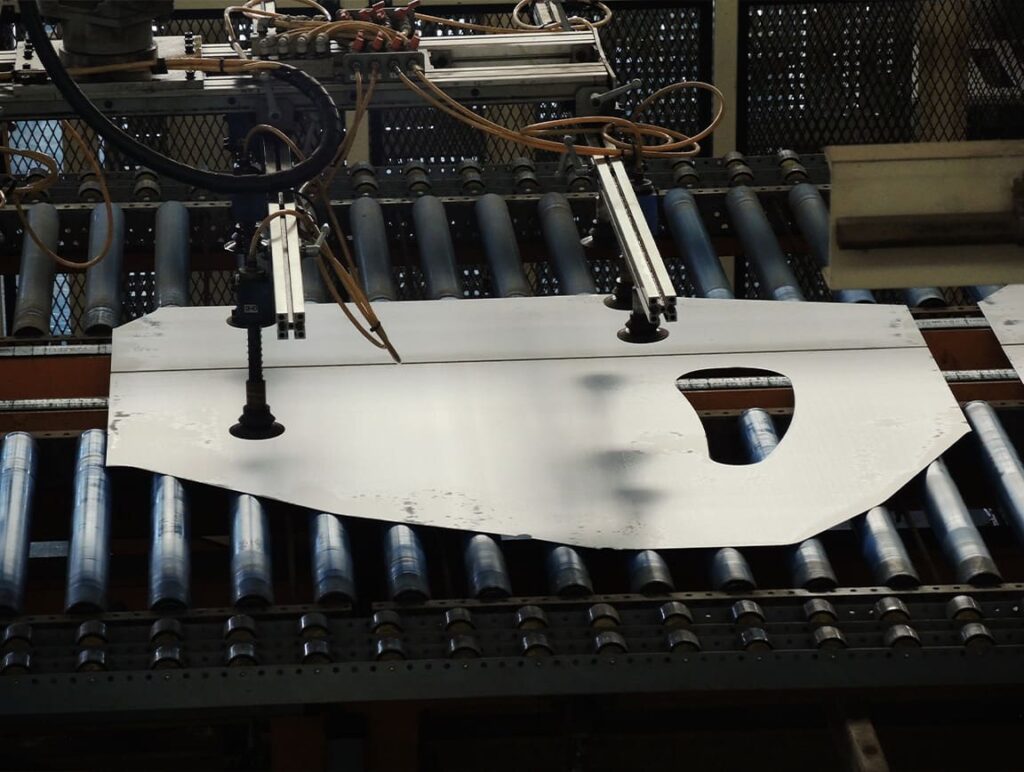

Automotive

We play a pivotal role in the automobile manufacturing supply chain, processing, distributing and selling automotive steel sheet, meeting the various needs of automobile manufacturers in Japan and other countries.

To address the worldwide tightening of environmental regulations in recent years, we are focusing on strengthening the supply chain for light and sturdy high-tensile steel sheet that reduces vehicle weight. Taking advantage of our network:the global four key regions (Japan, China, ASEAN and the Americas)—including a new processing and sales facility in Mexico—we coordinate with JFE Group manufacturing facilities to meet the local procurement needs of our customers.

Shipbuilding, Construction Machinery and Energy

We procure steel sheet and plate from JFE Steel and other steel manufacturers around the world that is used to build ships, construction and industrial machinery, offshore wind power generators, bridges, roofs, walls, etc. We meet customer needs with timely and proactive proposals and communication.

In Japan, through our typical equipment functions such as process numerous pre-fabricated blocks for ship building companies, we provide processed plate which contribute to the efficiency in construction sites.

We are also pursuing various projects overseas, including crafting a steel sales and processing supply chain for offshore wind farms and enhancing our product lineup through investments in local manufacturers in Vietnam and other countries.

Raw Materials & Machinery

Main Steel Raw Materials

Our primary focus is on maintaining a stable supply of the iron ore and coal essential to the ironmaking business to JFE Steel. We are also expanding our imports, exports and cross-border business involving raw materials such as blast furnace slag*1 .

As demand for coking coal fluctuates according to the market environment and customer coal grade needs at the time, we collect information on a daily basis to meet customer needs. We are currently prioritizing coal that is more in line with environmental measures. We procure iron ore from suppliers operating mines in Australia and Brazil, where there are abundant resources. To reduce CO2 emission, we are also focusing on raw materials manufactured using hydrogen and other methods*2 .

Metallic Materials

We procure ferrous alloys, nonferrous metals and special metals—auxiliary raw materials that determine the properties of steel—from suppliers around the world, and sell them to JFE Steel and domestic and overseas steelmakers.

As various risks emerge, we leverage our global network to diversify sources and countries of purchase to ensure a stable supply of competitive raw materials to steelmakers in Japan. As demand increases overseas, especially in Asia, we are strengthening our procurement capabilities through such means as participating in a ferrosilicon manufacturing project in Malaysia and trilateral transactions.

Shipbuilding, Construction Machinery and Energy

We procure steel sheet and plate from JFE Steel and other steel manufacturers around the world that is used to build ships, construction and industrial machinery, offshore wind power generators, bridges, roofs, walls, etc. We meet customer needs with timely and proactive proposals and communication.

In Japan, through our typical equipment functions such as process numerous pre-fabricated blocks for ship building companies, we provide processed plate which contribute to the efficiency in construction sites.

We are also pursuing various projects overseas, including crafting a steel sales and processing supply chain for offshore wind farms and enhancing our product lineup through investments in local manufacturers in Vietnam and other countries.

Raw Materials & Machinery

Main Steel Raw Materials

Our primary focus is on maintaining a stable supply of the iron ore and coal essential to the ironmaking business to JFE Steel. We are also expanding our imports, exports and cross-border business involving raw materials such as blast furnace slag*1 .

As demand for coking coal fluctuates according to the market environment and customer coal grade needs at the time, we collect information on a daily basis to meet customer needs. We are currently prioritizing coal that is more in line with environmental measures. We procure iron ore from suppliers operating mines in Australia and Brazil, where there are abundant resources. To reduce CO2 emission, we are also focusing on raw materials manufactured using hydrogen and other methods*2 .

Metallic Materials

We procure ferrous alloys, nonferrous metals and special metals—auxiliary raw materials that determine the properties of steel—from suppliers around the world, and sell them to JFE Steel and domestic and overseas steelmakers.

As various risks emerge, we leverage our global network to diversify sources and countries of purchase to ensure a stable supply of competitive raw materials to steelmakers in Japan. As demand increases overseas, especially in Asia, we are strengthening our procurement capabilities through such means as participating in a ferrosilicon manufacturing project in Malaysia and trilateral transactions.

Metal Recycling

Many countries have declared their intention to become carbon neutral by 2050. As a company, we are contributing to the rise of a low-carbon society by engaging in steel scrap trade in Japan and overseas.

Using steel scrap as a raw material can reduce the amount of CO2 generated during steelmaking Steel mills around the world are therefore increasing the amount of steel scrap consumption. We provide steel scrap via various kinds of trade including domestic trade, export trade and offshore trade leveraging our purchasing and sales networks and storage yards in Japan and overseas.

Chemicals

We leverage our domestic and overseas networks to sell a wide variety of raw materials produced mainly via coal chemistry to various industries in Japan and overseas.

The raw materials we carry are used in various applications. Examples tires, agricultural fertilizers, electrodes for secondary lithium-ion batteries, and electronic components used in 5G base station antennas. We also sell argon gas, which is essential for manufacturing semiconductors. All of these products incorporate byproducts generated during the steelmaking process.

Machinery & Materials

We are offering materials and facilities to steelworks in Japan and overseas, in particular, ASEAN, India, South America and Europe. With Taking advantage of strong relationships with suppliers across multiple industries, we aim for proposal-based sales from the customer’s point of view.

Our attempts are now not limited to the steel industry, but also entering the electric power industry and contributing to the spread of renewable energy. Focusing on the deposits on piping and equipment that affect the power generation efficiency of geothermal power generation, we are working with electric power companies and suppliers to propose the best chemicals to reduce the deposits and it is effective now. This proposal-based sale has been highly evaluated by many electric power companies, and we are expanding our activity to thermal power, hydraulic power, nuclear power plants in all over Japan.

Governance

Corporate Governance

We shall establish a system to enhance both the soundness and efficiency of business administration.